Resione G217 Clear Non-yellowing Tough ABS Like 3D Printer Resin (1kg)

| Brand: Resione |

Resione G217 Clear Non-yellowing Tough ABS Like Resin

Descriptions

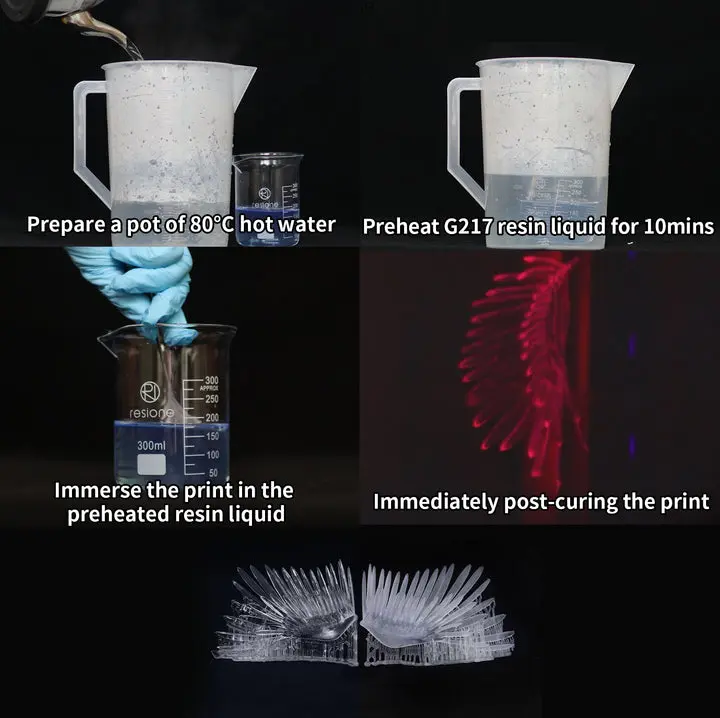

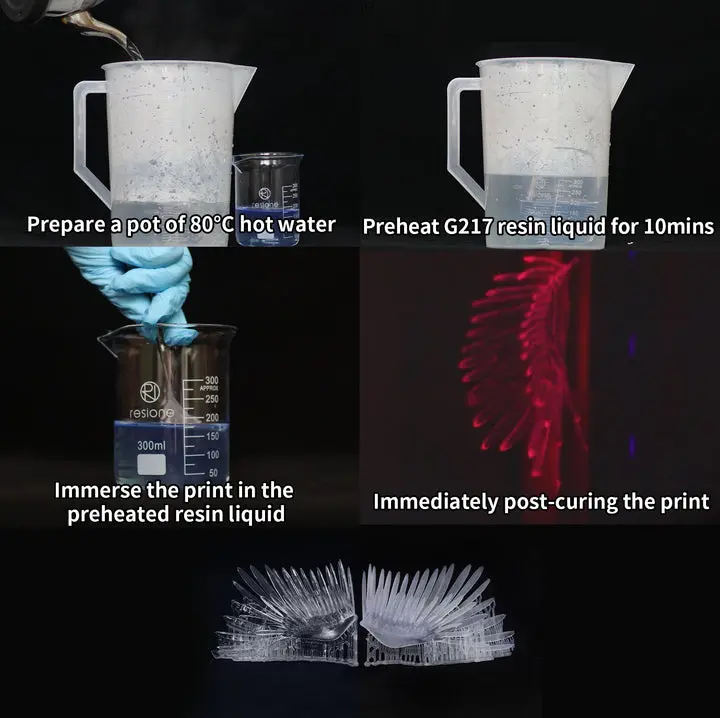

- Mixed with F69/F39/F39T

Tough resin K/M58/M68/G217 can be mixed with F69/F39/F39T resin, which can make the printed parts tougher, more durable, and not brittle for a long time.

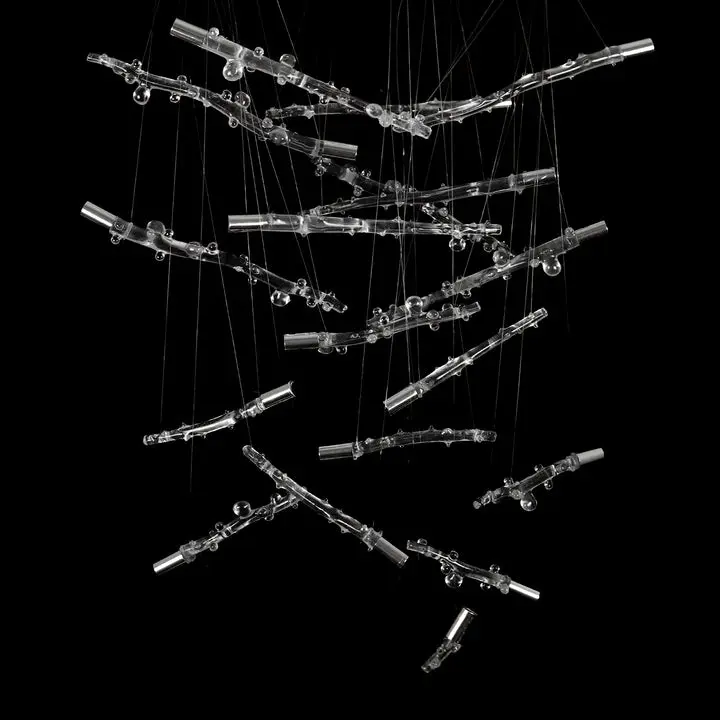

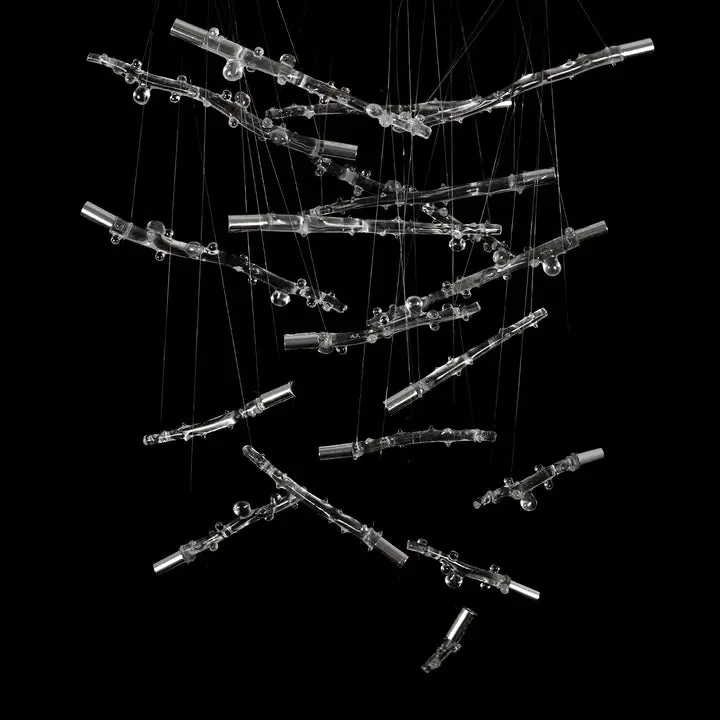

- High transparency raw material

The raw materials of G217 resin are all clear and transparent. RESIONE strictly controls the production process, and no impurities remain in the raw materials. After sanding and spraying clear varnish or G217 resin, the print will become completely transparent (slightly bluish).

- Non-yellowing

Ordinary resin will slowly turn yellow over time, but G217 resin will not. G217 prints may turn yellow after post-curing, but will fade within a few days until the transparent color is restored.

- Sturdy like ABS

The mechanical properties of the G217 resin prints are similar to tough thermoplastic materials, with high tensile strength and excellent impact strength. The prints can be machined repeatedly.

- High-quality raw materials

RESlONE prioritizes user care over cost considerations, selecting high-purity, low-irritation premium raw materials from around the world.

Compatible 3D Printer

- All series of Anycubic,Elegoo,Nova3d,Peopoly,Phrozen,Epax,Creality,Zortrax, BIQU, QIDI, UNIZ, Flashforge, Voxelab, Longer, Uniformation etc. UV 385-410nm LCD resin 3D printer

- All series of Anycubic,Asiga, Solus series, Miicraft, Kudo3d, Flashforge,Makex,Shining etc. UV 385-410nm DLP resin 3D printer

Applications

- Toy figures

- Special effects or scene models

- Artistic works

- Scientific research

- Highly transparent parts

- Jigs and fixtures

- Snap-fit designs

- Functional parts

Material performance parameters

| METHOD | DATA | |

| Viscosity(25℃)(mpa.s) | ASTM:D4212-10 | 864 |

| Liquid density(g/cm³) | ASTM:D4052-22 | 1.116 |

| Solid density(g/cm³) | ASTM:D792-20 | 1.189 |

| Shore Hardness(D) | ASTM:D2240-05 | 91 |

| Tensile Strength(MPa) | ASTM: D638-14 | 62.3 |

| Tensile Modulus(MPa) | ASTM: D638-14 | 1880 |

| Elongation at Break | ASTM: D638-14 | 17.88% |

| Flexural Strength(MPa) | ASTM: D790-10 | 80.4 |

| Flexural Modulus(MPa) | ASTM: D790-10 | 2250 |

| Notched IZOD(J/m) | ASTM:D256-10 | 34.7 |

| Water Absorption(24hr) | ASTM:D570-22 | 1.07% |

?unique=4cdf2ca)

?unique=4cdf2ca)