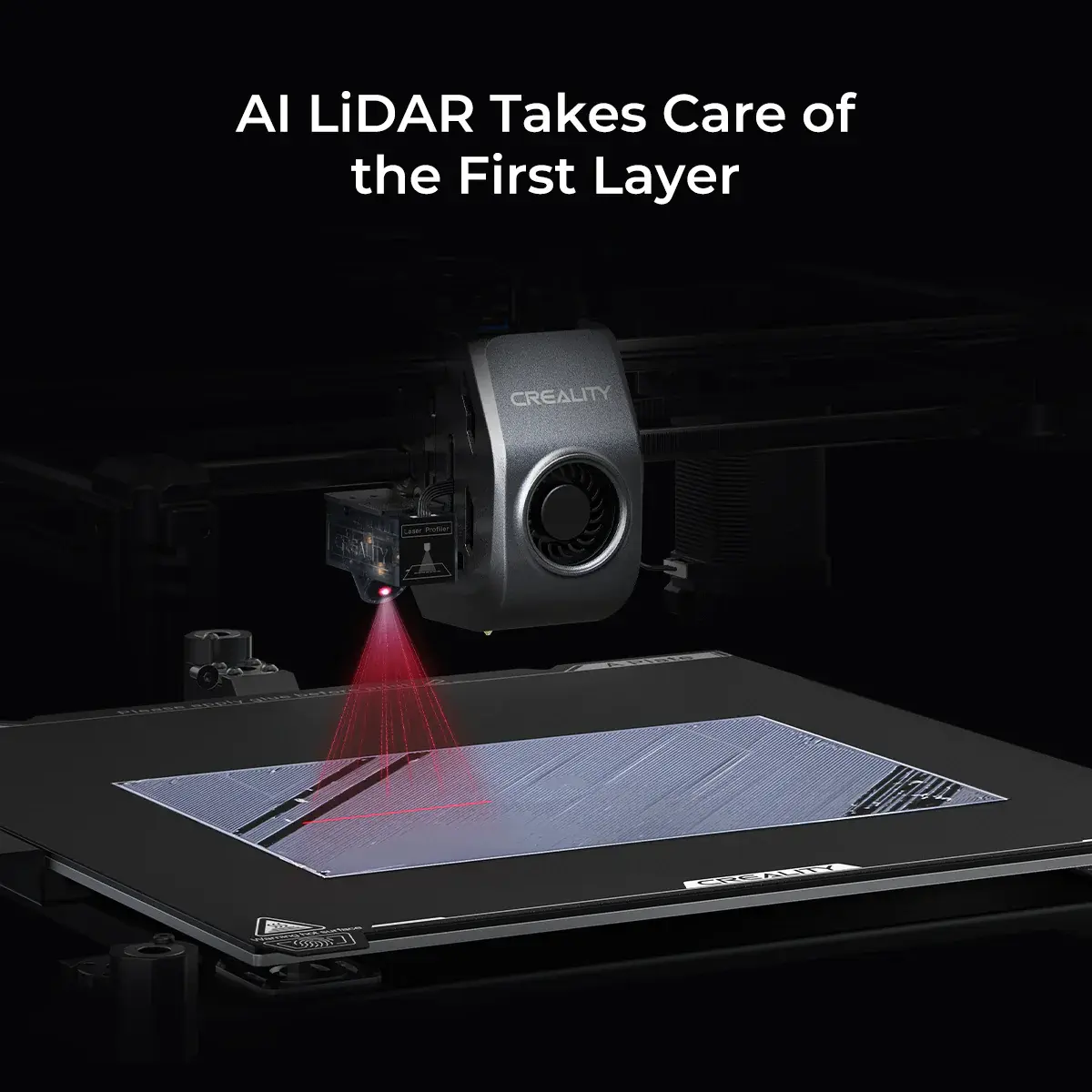

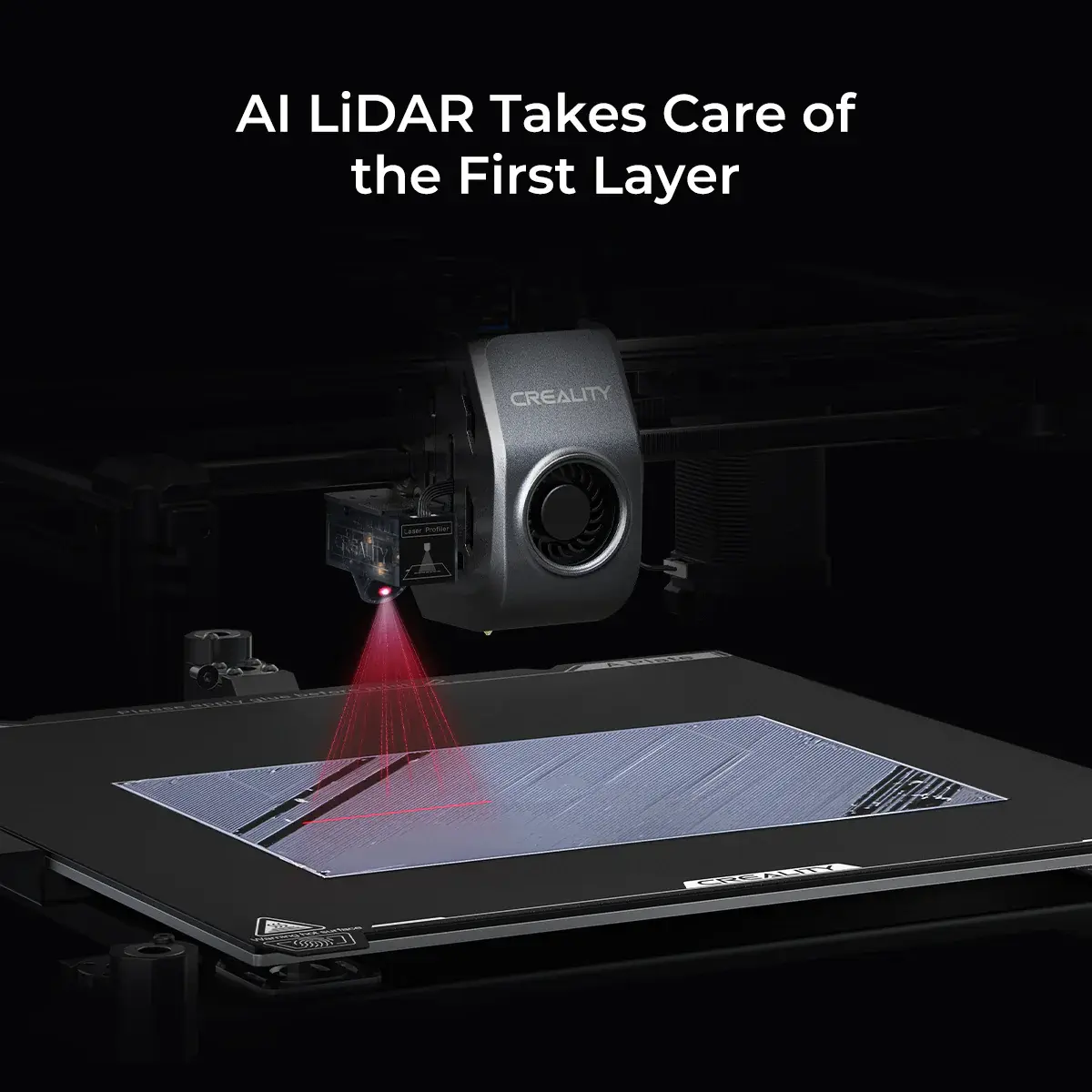

AI LiDAR Takes Care of the First Layer

Still worry about the first layer? Just leave it all to the AI LiDAR of K1 Max.The 1 μm resolution LiDAR will scan the first layer on its own. It will pause printing and tell you immediately if something goes wrong.

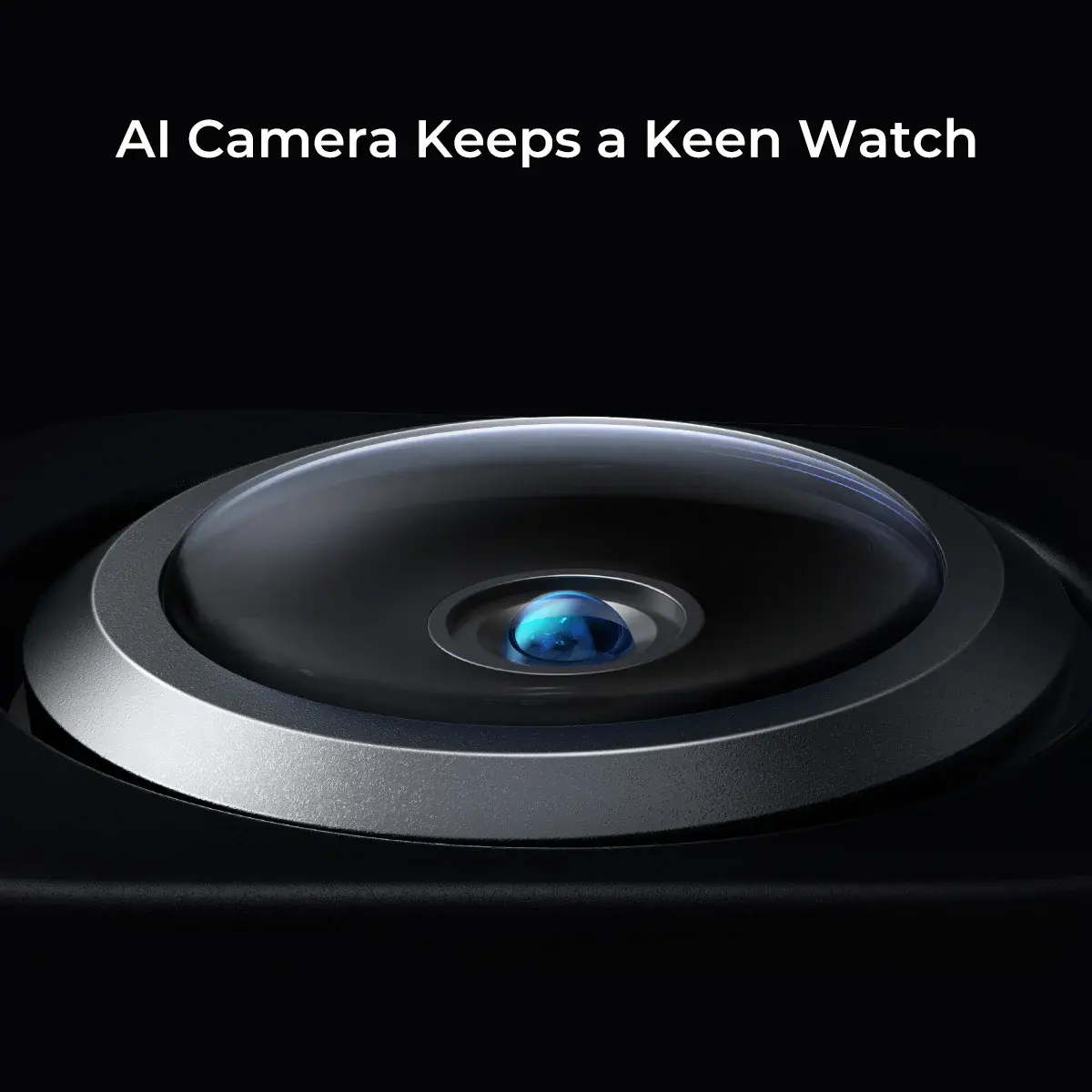

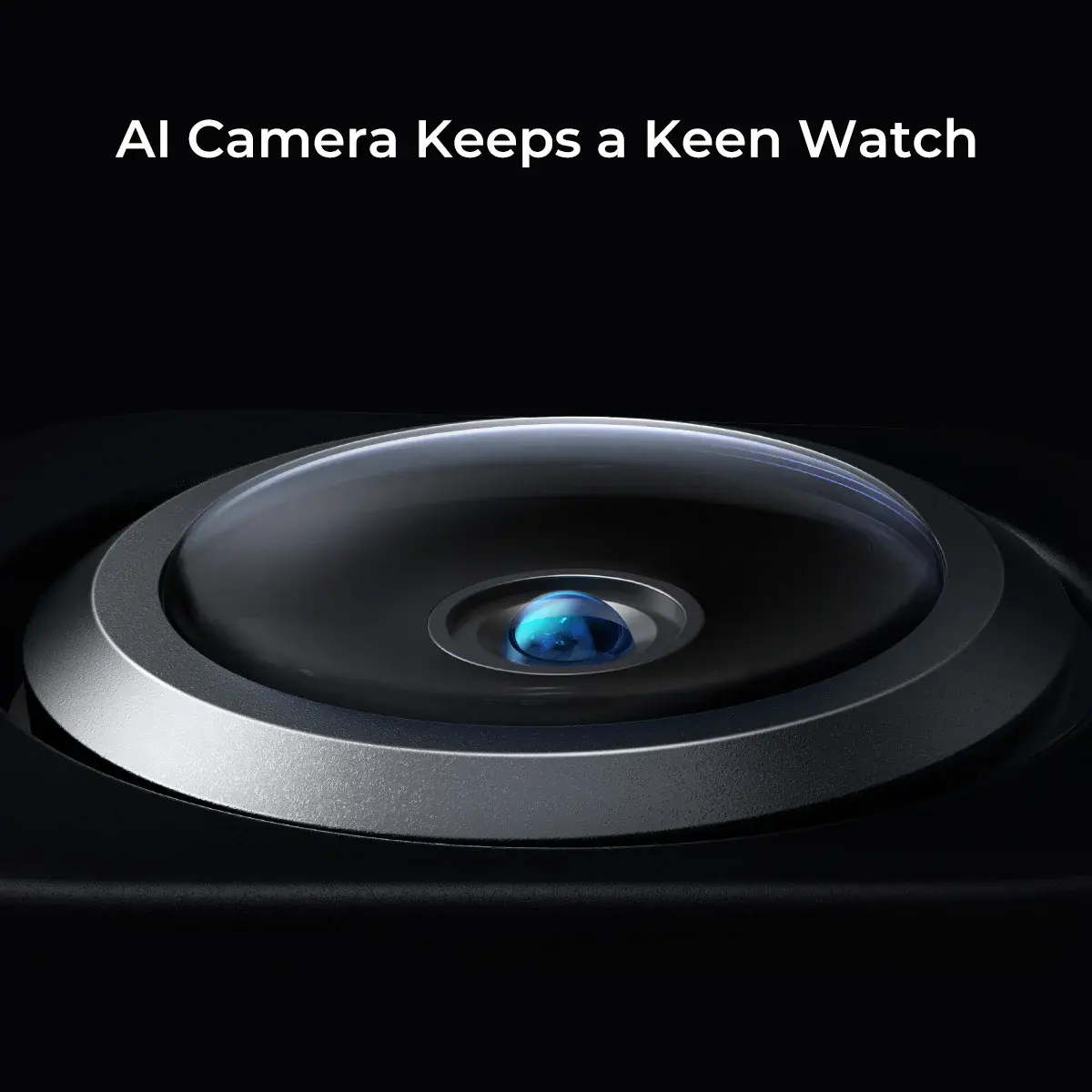

AI Camera Keeps a Keen Watch

K1 Max uses an AI camera to watch over spaghetti failure, foreign objects, debris, etc.

It will alert you when an error occurs.

It also supports real-time monitoring and creates time-lapses for sharing.

Hands-free Auto Leveling

Strain sensors in the heatbed generate an accurate leveling mesh for auto compensation. A G-sensor in the printhead measures the resonance frequencies of high-speed printing and shapes the input to mitigate it.

AI LiDAR Takes Care of the First Layer

Still worry about the first layer? Just leave it all to the AI LiDAR of K1 Max.The 1 μm resolution LiDAR will scan the first layer on its own. It will pause printing and tell you immediately if something goes wrong.

AI Camera Keeps a Keen Watch

K1 Max uses an AI camera to watch over spaghetti failure, foreign objects, debris, etc.

It will alert you when an error occurs.

It also supports real-time monitoring and creates time-lapses for sharing.

Hands-free Auto Leveling

Strain sensors in the heatbed generate an accurate leveling mesh for auto compensation. A G-sensor in the printhead measures the resonance frequencies of high-speed printing and shapes the input to mitigate it.

Respecting your privacy is our priority.

Allow the use of cookies from this website on this browser?

We use cookies to provide improved experience on this website. You can learn more about our cookies and how we use them in our Cookie Policy.

Allow all cookiesOnly allow essential cookies