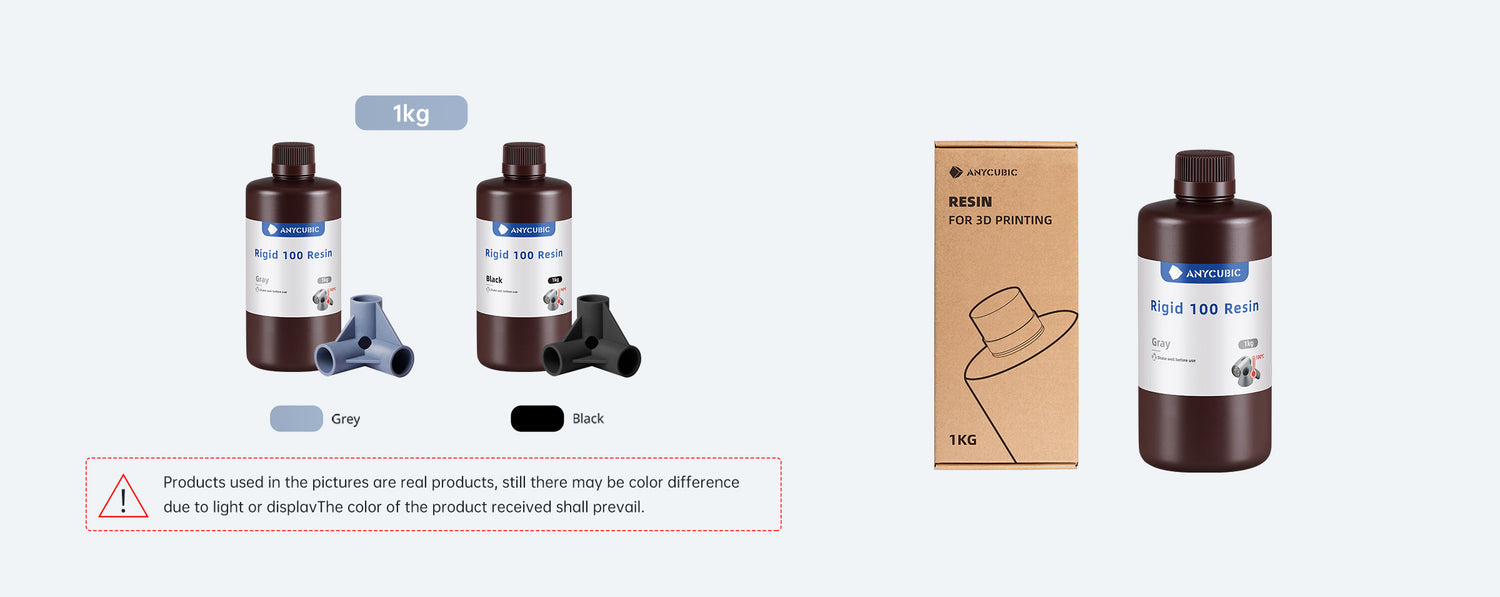

Anycubic Rigid 100 Resin

Outstanding Thermal Resistance

Models printed using Anycubic Rigid 100 Resin have high strength comparable to industrial-grade materials and can withstand temperatures as high as 100°C.The recommended cleaning time for printing models is to clean with 95% ethanol or isopropanol for 6 minutes and spray with a spray bottle for 1 minute. And the suggested curing time is 30 minutes under UV light in hot air at 60 ℃.

Extra Toughness, Excellent Rigidity

Anycubic Rigid 100 Resin toughness is twice that of ordinary standard resin, with toughness ungraded to 90Mpa, thus it's more resistant to deformation when bearing the same pressure, and less likely to be distorted.

UV Light Curing Increases the Bending Strength by 100%

As the UV curing time and temperature increase, the model's rigidity will also increases. When you set the curing mode to 80°C for 60 minutes, the bending strength can reach 180Mpa.

Higher Performance with Photon Mono M7 Pro

Anycubic Photon Mono M7 Pro widely compatible with all resin 3d printers on the market, and works best with Rigid 100 Resin, as Anycubic M7 Pro 3D Printer features an Dynamic Temperature Control Resin Vat that enhances resin flow and helps reduce resin's viscosity, thus ensuring reliable, rapid printing with Anycubic Rigid High-Temp Resistant 100 Resin.

Low-odor and Pleasant Printing

Anycubic Rigid 100 Resin adopts a low-odor formula, which creats a pleasant printing environment.

Anycubic Rigid 100 Resin

Exceptional Adaptability, Enhanced Rigidity

Outstanding Thermal Resistance

High-temperature resistant resin prints strong models, up to 100°C. Resistant to deformation in 60-100°C environments. Ideal for outdoor gear, electronics, and high-strength tools.It is currently the strongest resin offered by Anycubic.

Extra Toughness,Excellent Rigidity

Its toughness is twice that of ordinary rigid resin, with toughness ungraded to 90Mpa, thus it's more resistant to deformation when bearing the same pressure, and less likely to be distorted.

Higher Performance with Photon Mono M7 Pro

The Anycubic Photon Mono M7 Pro is optimized for Rigid 100 Resin, featuring a Dynamic temperature control resin vat that reduces resin viscosity and enhances flow.

MODEL PRINTS

Resin Parameters

| Wavelength | 365-405nm | Elongation at Break | 5-7% |

| Density | 1.14 g/cm³ | Flexural strength | 95-110 MPa |

| Viscosity | 950-1150 mPa·s | Felxural modulus | 2800-3400 MPa |

| Surface Hardness | 88-90 D | Tensile Strength | 80-85 MPa |

| First Layer Exposure | 23-35s | Normal Exposure | 2-2.8s |

| Recommended Printing Temperature | higher than 25°C | Shelf Life | 1.5Years |

| Resin Cleanup Time | 95% ethanol /isopropyl alcohol | Curing Method | 60℃ 30mins under UV light and in a hot environment |

| Heat Distortion Temperature | 105℃ |

Recommended Printing Parameters

| Printer Model | Layer Thickness | Exposure Time | Off Time | Bottom Exposure Time | Bottom Layers | Anti-alias | Z Lift Distance | Z Lift Speed | Z Retract Speed |

|---|---|---|---|---|---|---|---|---|---|

| Photon Mono M7 Max | 0.05mm | 2s | 0.5s | 30s | 5 | 1 | 8mm | 6mm/s | 6mm/s |

| Photon Mono M7 | 0.05mm | 2.2s | 2s | 25s | 4 | 1 | 8mm | 6mm/s | 6mm/s |

| Photon Mono 4 | 0.05mm | 2.8s | 1s | 30s | 5 | 1 | 6mm | 4mm/s | 6mm/s |

| Photon Mono 4 Ultra | 0.05mm | 2.6s | 1s | 30s | 5 | 1 | 5mm | 8mm/s | 8mm/s |

| Photon Mono M7 Pro | 0.05mm | 2s | 2s | 35s | 5 | 1 | 8mm | 6mm/s | 6mm/s |

| Photon Mono M5s Pro | 0.05mm | 2.8s | 1s | 23s | 5 | 1 | 8mm | 6mm/s | 6mm/s |

| Photon Mono M5s | 0.05mm | 2.8s | 1s | 23s | 5 | 1 | 8mm | 6mm/s | 6mm/s |

| Photon Mono M5 | 0.05mm | 2.8s | 1s | 23s | 5 | 1 | 8mm | 6mm/s | 6mm/s |

| Photon Mono X 6Ks | 0.05mm | 2s | 1s | 23s | 5 | 1 | 6mm | 4mm/s | 6mm/s |

| Photon Mono 2 | 0.05mm | 2.5s | 1s | 25s | 5 | 1 | 5mm | 4mm/s | 6mm/s |

| Photon Mono M3 Max | 0.05mm | 2.8s | 1s | 30s | 6 | 1 | 8mm | 4mm/s | 4mm/s |

| Photon Mono X2 | 0.05mm | 2s | 1s | 23s | 5 | 1 | 6mm | 4mm/s | 6mm/s |

| Photon M3 Premium | 0.05mm | 2.5s | 1s | 25s | 5 | 1 | 6mm | 6mm/s | 6mm/s |

| Photon X 6K | 0.05mm | 2s | 1s | 25s | 6 | 1 | 6mm | 4mm/s | 6mm/s |

| Photon Mono 4K | 0.05mm | 2.5s | 1s | 25s | 6 | 1 | 5mm | 4mm/s | 6mm/s |

Color Type

Instructions for Use

(1) Before use:

Shake the liquid resin before use;Clean the resin tank and the molding platform to keep the bottom of the resin tank in light transmission.

(2) When using:

Unscrew the cap and add it to the resin tank according to the equipment requirements;Select the correct print parameters and settings for printing

(3) After use:

After printingplease use the matching tools for post-processing,including blade,diagonal pliers,tweezers,containers,gloves;clean with water.

(4) Post-processing steps:

Remove the printed model from the molding platform with a blade; Submerge the model in the cleaning solution, rinsed or ultrasonically washed, then takenout and drained; ANYCUBlC Wash and Cure machines are suggested to ensure better effect.Proper processing, such as removing support, polishing, coloring, etc.

(5) Wastewater post-process:

A. Do not discharge wastewater directly into the sewer to avoid contaminating groundwater.

B. Heat the wastewater,let most of the water evaprorate,and then discard the residue after curing by curing machine and sunlight.

Precautions

1.The ideal condition for storing uncured resin is a cool, dark place at room temperature and protect from light to avoid high temperature or sunlight.

2.Suggested operating temperature is 25℃, and a low temperature may affect the printing effect, thus, the resin can be properly preheated before use (not more than 70°C).

3.If the resin pigment settles, it can be used after stirring or shaking.

4.To ensure the performance of the resin, please take out the model in time after cleaning to avoid deteriorating performance of the resin after the long time immersion in IPA and absorption of water.

5.To ensure the mechanical properties of the model, please perform post-curing in time after cleaning and drying.

6.To ensure the ideal performance of the curable material it is necessary to control the intensity and time of the light source after curing.Therefore,

The following steps are recommended:

(1) The intensity of mercury lamp or LED light source is 5-10mW/m2,and the duration is no more than 1hour (self-regulation):

(2) The exposure time in the sun (summer)is around 1 hour;

(3) Proximity or long -term exposure under strong light sources such as high power high-pressure mercury lamps is prohibited

(4) It is recommended to print in a dark room or be covered with a lid while printing as resin is a photosensitive material.

(5) To avoid yellowing caused by long-term curing of High Clear Resin, please reduce the exposure time by half compared with other resin colors.

(6) Black resin may appear partially transparent in thin walls (<0.5mm), so the greater thickness can achieve better color effects.

?unique=e7750bb)

.webp?unique=0bad678)

?unique=e7750bb)

.webp?unique=0bad678)