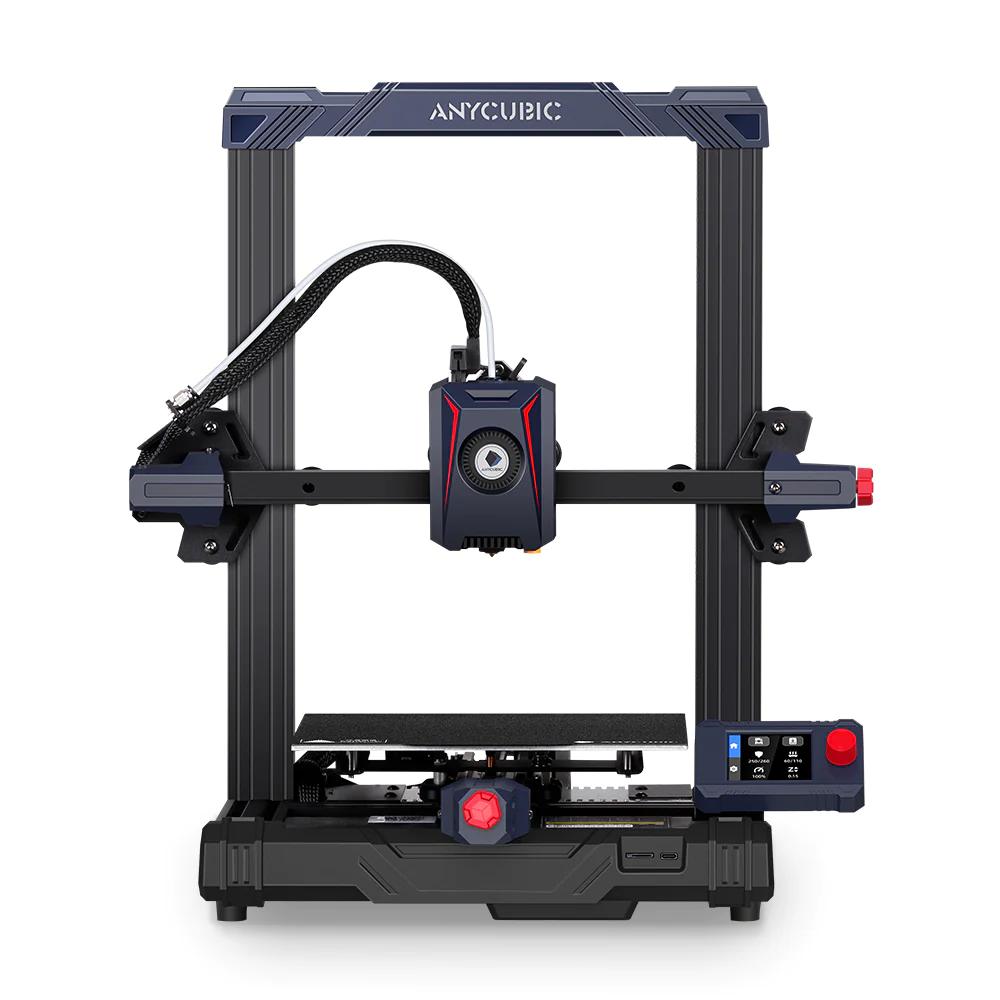

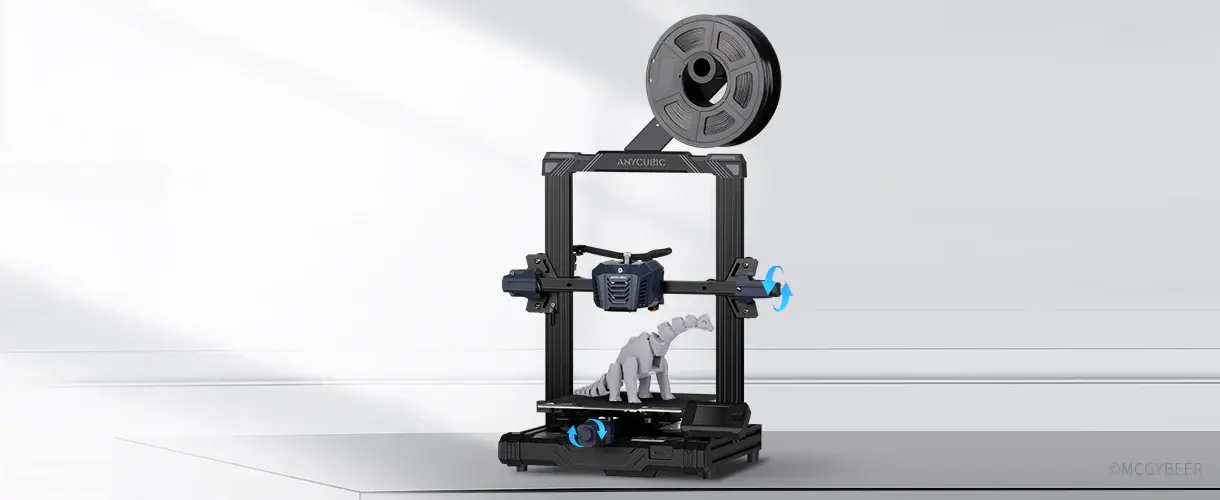

The Anycubic Kobra Neo 3D Printer is a high-performance and user-friendly device designed for both novice and experienced users. With its fast printing speeds, dual-extruder design, large build volume, and heated tempered glass bed, this 3D Printer is perfect for producing large models, multi-color prints, and more. Experience exceptional 3D Printing with the Anycubic Kobra Neo.

The Anycubic Kobra Neo is compatible with a range of 3D Printing software, including Cura and Simplify3D. The software is easy to use and provides a range of options for users to customize their prints, including layer height, speed, and temperature settings. The printer also supports a range of file formats, including STL, OBJ, and G-code, making it easy to import and print models from a variety of sources.

Features Of Anycubic Kobra Neo 3D Printer

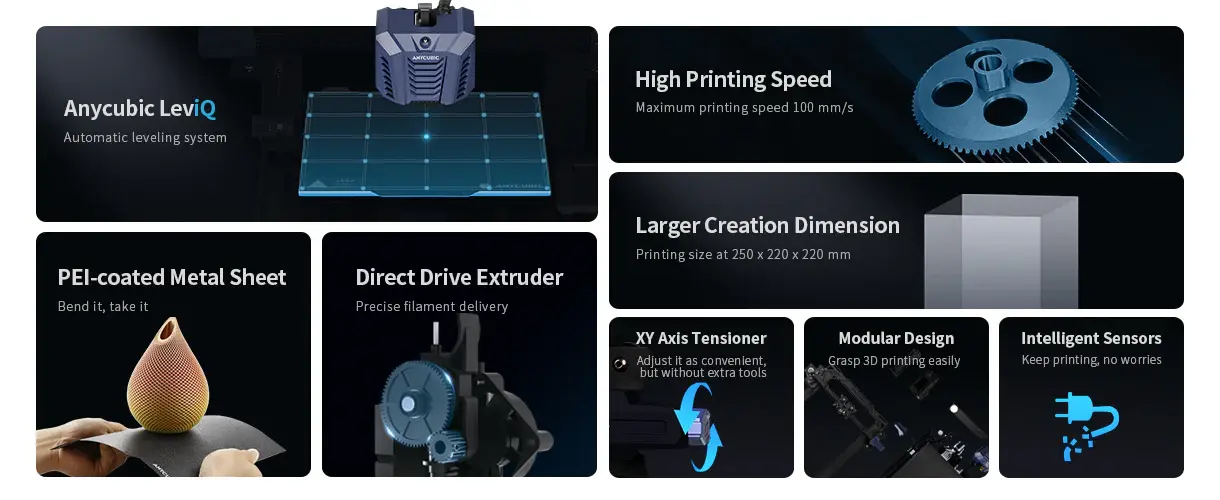

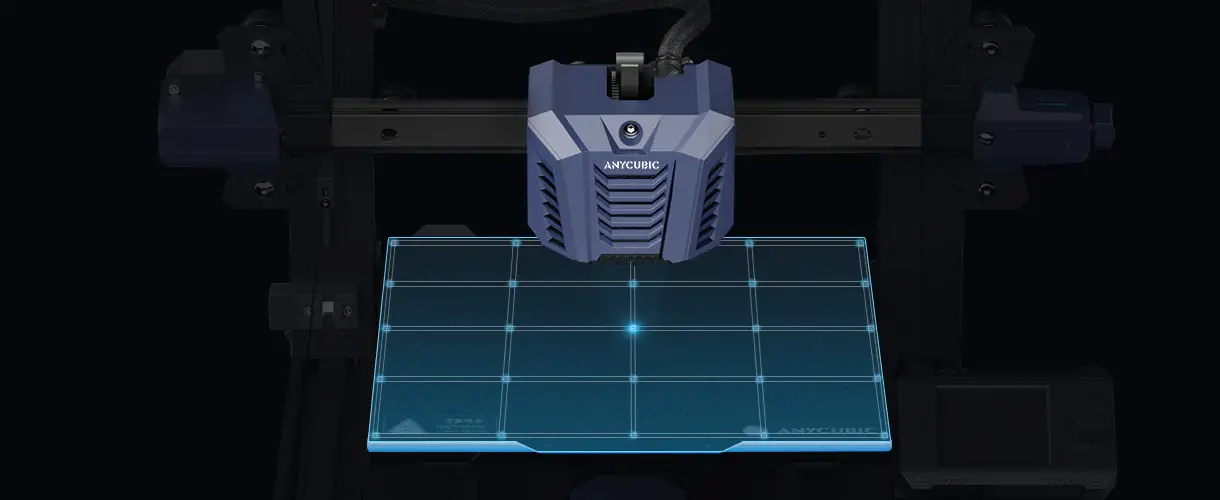

One-touch Leveling

The self-invented Anycubic LeviQ automated levelling technology is included. Leveling has never been easier thanks to the 25-point sophisticated and exact calibration and hardware algorithm that automatically compensates for the unevenness of the hotbed.

Integrated Extruder for Precise Filament Extrusion

Due to the extruder's integration with the hot end, replacing the filament is simpler and has a reduced failure rate. Additionally, the filament may be delivered more effectively and precisely with an integrated extruder.

Easy Removal with Adhesive PEI Spring Steel Platform

The printing platform is comprised of wear-resistant, less likely to break, and bendable magnetic spring steel. By bending the build platform just a little, the finished miniatures can be quickly removed. Easy installation and removal are provided by the magnetic design.

10 Minutes Easy Set Up

The KOBRA Neo is a wonderful option for a beginner-friendly FDM 3D Printer because of its 5-modular design, which enables the printer to be set up in less than 10 minutes.

High Printing Speed

It is possible to shorten 3D Printing times without sacrificing quality with the Anycubic KOBRA Neo, which prints at an average speed of 60 mm/s and as fast as 100 mm/s.

Larger Creation Dimension

The Anycubic KOBRA Neo features a 34.4% larger printing volume than the Anycubic Mega S of the previous generation, at 12.1 litres. The printing area measures 220*220*250 mm, which is the same size as a size 5 football

Worry-free Smart Sensors

By preventing the printing failure brought on by the power outage and shortage of filament, the standard power outage restarting sensor and the optional filament run-out sensor decrease filament waste and save time.

Knobs for Easy Adjustment

The XY axis belt-knobs tensioner's make it simple to modify the string tightness. Only your hands are needed; no other instruments are needed.

One-touch Leveling

Equipped with the self-innovated Anycubic LeviQ automatic leveling system. 25-point intelligent and precise calibration and hardware algorithm to automatically compensate for the unevenness of hotbed, leveling has never been so easy.

Integrated Extruder for Precise Filament Extrusion

The extruder is integrated within the hot end, making it easier to replace the filament with a lower failure rate. Moreover, an integrated extruder can deliver the filament more efficiently and precisely

Adhesive PEI Spring Steel Platform for Easy Removal

The printing platform is made of magnetic spring steel, which is wear-resistant, less breakable, and bendable. The finished miniatures can be removed quickly by bending the build platform slightly. The magnetic design makes it easy to install and remove.

10 Minutes Easy Set Up

The 5-modular design makes it possible to set up the printer within 10 minutes, which makes Kobra Neo a good choice for a beginner-friendly FDM 3D printer

High Printing Speed

Anycubic Kobra Neo prints at a typical speed of 60mm/s and reaches 100mm/s at its highest, which is possible to speed up 3D printing times without losing quality.

Larger Creation Dimension

Compared to the previous generation Anycubic Mega S, The Anycubic Kobra Neo has a 34.4% increase in printing volume to 12.1 liters. The printing size is 220*220*250 mm, which is equivalent to the size of a standard size 5 football

Worry-free Smart Sensors

The standard power outage resuming sensor and the optional filament run-out sensor reduce filament waste and save time by avoiding the printing failure caused by the power outage and lack of filament.

Knobs for Easy Adjustment

The knobs of the XY axis belt-tensioner make it easy to adjust the string tightness. No additional tools are required, just with your hands.

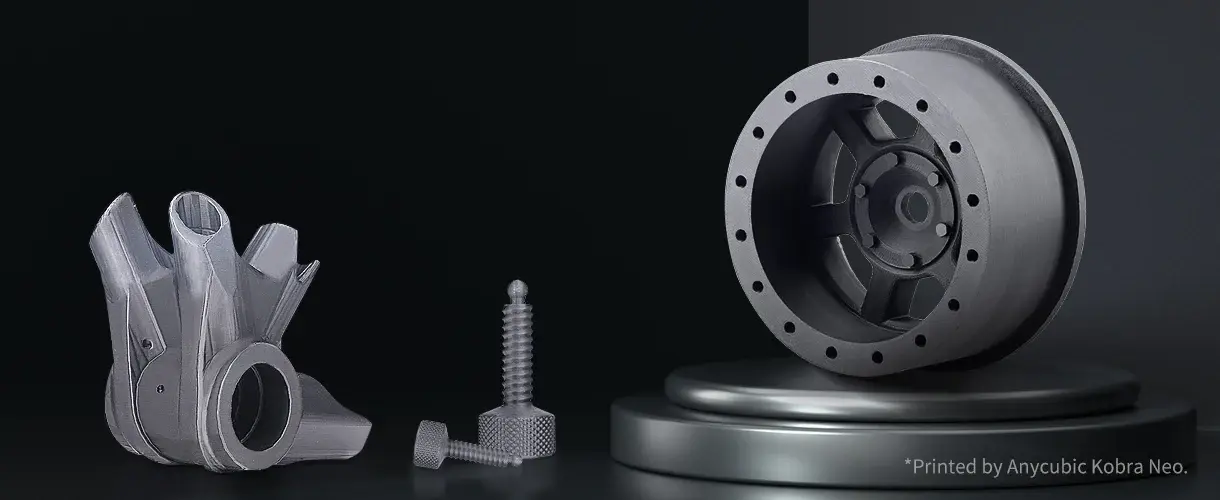

Anycubic Kobra Neo

Models Display