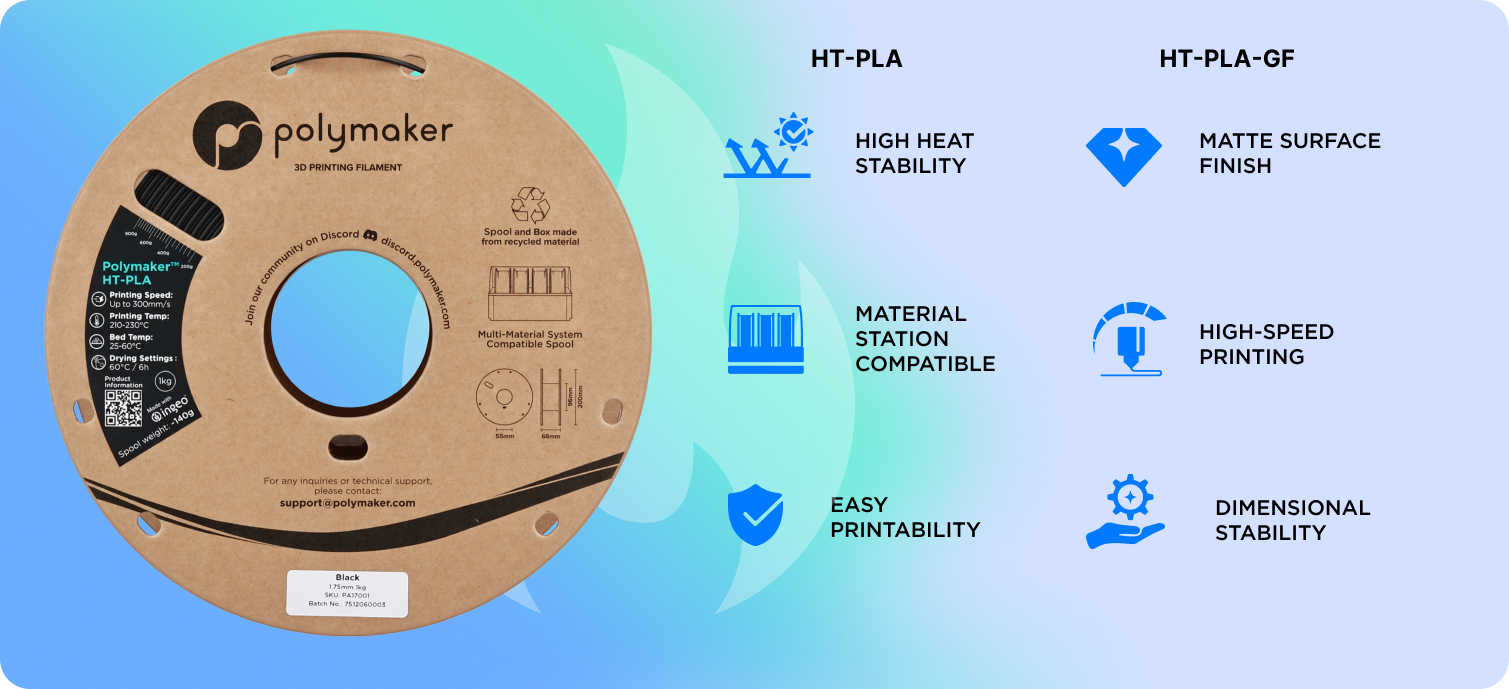

Polymaker Redefines PLA with High-Temperature Variants - HT PLA & HT PLA-GF

Introduction:

Polymaker has just introduced two new filaments HT PLA and HT PLA-GF specially designed to push the boundaries of the possibilities of PLA. Polymaker's newly introduced PLA variants offer heat resistance and mechanical strength and also maintains the ease of use that makes PLA so popular.

What Makes Them Different?

Standard PLA is known for its easy printing ability, it typically softens at around 60°C. Polymaker’s HT-PLA increases this to approximately 150°C without the need for post processing. HT-PLA-GF is reinforced with glass fibers, which delivers superior strength, dimensional stability, and temperature resistance.

HT-PLA filament is a premium, heat-resistant 3D printing material designed to withstand temperatures up to 150°C without warping or deforming. HT-PLA combines the durability of industrial-grade materials with the easy printability of standard PLA.

Key Features:

- Heat resistance up to 150°C

- Enhanced mechanical strength

- Glass fiber option for added durability

- Compatible with most FDM 3D printers

- Available in multiple colors

Uses & Importance

These new filaments open opportunities for creating functional parts, automotive components, and prototypes that need to perform in high temperature conditions, it offers all the features along with the user friendly nature of PLA.

1- Complexity Without Limitations

HT-PLA delivers the trusted ease of PLA with the advanced thermal resistance needed for high-demand applications. Push creative boundaries and print intricate designs built to perform under the heat.

2- Heat Stability up to 150°C

HT-PLA delivers heat stability up to 150°C—right off the print bed, no post-processing required.

3- Power Tool Storage

HT-PLA-GF comes in four rugged, power tool-inspired colors—perfect for organizing your workshop, garage, or shed. Anneal it to unleash mechanical strength at high temperatures that surpasses ABS

Conclusion

Polymaker’s high temperature PLA is a game changer for makers, engineers, and product designers who need to print stronger and heat resistant parts.